LOAD_SECTION_MACRO

Loads a macro section into the section list.

Description

Sections have to be loaded into the current model file to be able to be used in the model. Initially in a new model file the section list is empty. There are several ways to load in, or create a section: library section, macro section, user drawn section. In this case the macro section option is used. The command is analogous with the highlighted "Macro section..." button at the section administration dialogue in Consteel.

Syntax

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] Section parameters...

Command parameters

| Command parameter | Assignment | Value format | Input options |

|---|---|---|---|

| Object ID | Required | String | Local, variable |

| Macro type | Required | Predefined strings | Local, variable |

| Section name | Required | String | Local, variable |

| Material name | Optional | Predefined strings | Local, variable |

| Section parameters | Required | Numerical or string | Local, variable |

Object ID:

A string of characters that is used to identify the object that is being created. The string can contain letters, numbers and special characters as well. It can be defined as a variable that contains the string or directly as a string of characters between apostrophes.

For example:

LOADSECTION_MACRO $Section_ID [Macro type] [Section name] [Material name] [parameter1] [parameter2] _etc.

or

LOADSECTION_MACRO “Section ID 1” [Macro type] [Section name] [Material name] [parameter1] [parameter2] _etc.

Object ID-s have to be unique for every object across all object types (eg.: sections, members, plates, loads, etc.).

Macro type:

Type of macro to be used.

Available macro types:| Macro type name | Macro type |

|---|---|

| Welded sections | WLD-... |

| Welded I or H | WLD-IH |

| Welded box | WLD-BOX |

| Welded maltese | WLD-MALTESE |

| Welded half maltese | WLD-HALFMALTESE |

| Welded hat | WLD-HAT |

| Welded T | WLD-T |

| Welded WQ | WLD-WQ |

| Slant flange welded I or H | WLD-SLANTIH |

| Welded C | WLD-C |

| Hot rolled sections | HR-... |

| Hot rolled I or H | HR-IH |

| Hot rolled L | HR-L |

| Hot rolled U | HR-U |

| Hot rolled circular hollow section | HR-CHS |

| Hot rolled T | HR-T |

| Flat shape | HR-FS |

| Hot rolled rectangular hollow section | HR-RHS |

| Round bar | HR-RB |

| Cold-formed sections | CF-... |

| Cold-formed rectangular hollow section | CF-RHS |

| Cold-formed circular hollow section | CF-CHS |

| Cold-formed L | CF-L |

| Cold-formed C (simplified) | CF-C |

| Cold-formed Z (simplified) | CF-Z |

| Double mirrored sections | DM-... |

| Double mirrored C | DM-C |

| Double mirrored SIGMA | DM-SIGMA |

| Double mirrored user drawn | DM-UD |

| Reinforced concrete sections | RC-... |

| Rectangular beam section | RC-BeamRect |

| Rectangular column section | RC-ColRect |

| Circular column section | RC-ColCirc |

Section name:

Name of the section that will appear in the section list in Consteel. String of characters between apostrophes.

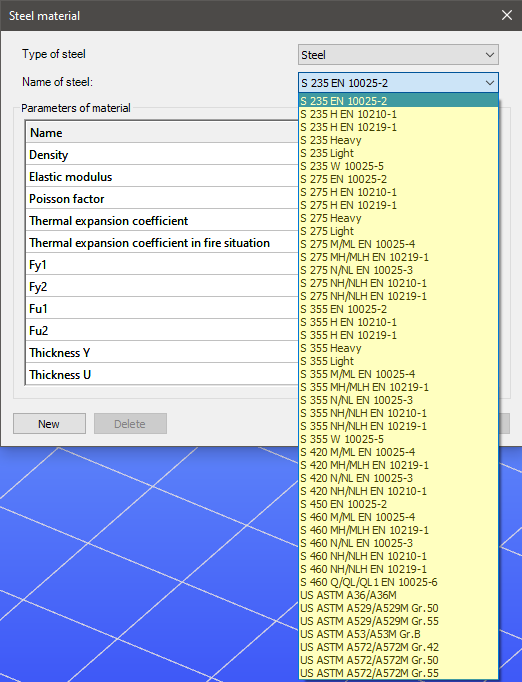

Material name:

Name of the material to be used for the section. String of characters between apostrophes. Exact match is necessary with the Consteel material names. This parameter is required for every macro type, except for the double mirrored macro types, where there is no material name parameter. Double mirrored macro sections inherit their material from their base section.

For example:

LOADSECTION_MACRO [Object ID] [Macro type] [Section name] "S 235 EN 10025-2" [parameter1] [parameter2] _etc.

The material names can be viewed in Consteel at the highlighted area of the material dialogue name dropdown.

Section parameters:

Section parameters like height, breadth, thickness, etc.. The quantity and meaning of the parameters depend on the macro type.

Detailed description of macro types

Welded sections

Welded I or H

Macro type:

WLD-IH

Parameters:

| Notation | Definition |

|---|---|

| b1 | Upper flange width |

| tf1 | Upper flange thickness |

| h | Section height |

| tw | Web thickness |

| b2 | Lower flange width |

| tf2 | Lower flange thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [b1] [tf1] [h] [tw] [b2] [tf2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-IH "WLD-IH (Descript)" "S 235 EN 10025-2" 100 10 200 6 100 10

Welded box

Macro type:

WLD-BOX

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| b | Section width |

| bw | Web plate width |

| tf1 | Upper flange thickness |

| tf2 | Lower flange thickness |

| tw1 | Web thickness on the left side |

| tw2 | Web thickness on the right side |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [bw] [tf1] [tf2] [tw1] [tw2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-BOX "WLD-BOX (Descript)" "S 235 EN 10025-2" 300 400 200 12 12 10 10

Welded maltese

Macro type:

WLD-MALTESE

Parameters:

| Notation | Definition |

|---|---|

| h1 | Section height |

| tw1 | Web thickness |

| b1 | Section width |

| tf1 | Flange thickness |

| h2 | Section height |

| tw2 | Web plate thickness |

| b2 | Section width |

| tf2 | Flange thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h1] [tw1] [b1] [tf1] [h2] [tw2] [b2] [tf2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-MALTESE "WLD-MALTESE (Descript)" "S 235 EN 10025-2" 400 10 200 20 300 8 150 16

Welded half maltese

Macro type:

WLD-HALFMALTESE

Parameters:

| Notation | Definition |

|---|---|

| h1 | Section height |

| tw1 | Web thickness |

| b1 | Section width |

| tf1 | Flange thickness |

| h2 | Section height |

| tw2 | Web plate thickness |

| b2 | Section width |

| tf2 | Flange thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h1] [tw1] [b1] [tf1] [h2] [tw2] [b2] [tf2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-HALFMALTESE "WLD-HALFMALTESE (Descript)" "S 235 EN 10025-2" 400 10 200 20 150 8 150 16

Welded hat

Macro type:

WLD-HAT

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| b | Section width at flange |

| bw | Distance between webs |

| tf | Flange thickness |

| tw | Width of webs |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [bw] [tf] [tw]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-HAT "WLD-HAT (Descript)" "S 235 EN 10025-2" 400 500 300 30 15

Welded T

Macro type:

WLD-T

Parameters:

| Notation | Definition |

|---|---|

| b | Upper flange width |

| tf | Upper flange thickness |

| h | Section height |

| tw | Web thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [b] [tf] [h] [tw]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-T "WLD-T (Descript)" "S 235 EN 10025-2" 100 10 200 6

Welded WQ

Macro type:

WLD-WQ

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| b | Lower flange width |

| bw | Distance between web plates |

| tf1 | Upper flange thickness |

| tf2 | Lower flange thickness |

| tw | Web thickness |

| c | Lower flange cantilever |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [bw] [tf1] [tf2] [tw] [c]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-WQ "WLD-WQ (Descript)" "S 235 EN 10025-2" 300 300 180 15 20 10 25

Slant flange welded I or H

Macro type:

WLD-SLANTIH

Parameters:

| Notation | Definition |

|---|---|

| b1 | Upper flange width |

| tf1 | Upper flange thickness |

| h | Section height |

| tw | Web thickness |

| b2 | Lower flange width |

| tf2 | Lower flange thickness |

| Alpha | Pitch of upper flange |

| b12 | Upper flange cantilever |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [b1] [tf1] [h] [tw] [b2] [tf2] [Alpha] [b12]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-SLANTIH "WLD-SLANTIH (Descript)" "S 235 EN 10025-2" 414 30 397 15 296 30 73 144

Welded C

Macro type:

WLD-C

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| t3 | Web thickness |

| b1 | Upper plate width |

| t1 | Upper flange thickness |

| b2 | Lower flange width |

| t2 | Lower flange thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [t3] [b1] [t1] [b2] [t2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 WLD-C "WLD-C (Descript)" "S 235 EN 10025-2" 200 6 60 10 100 12

Hot rolled sections

Hot rolled I or H

Macro type:

HR-IH

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| tw | Web thickness |

| tf | Flange thickness |

| r | Corner rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [tw] [tf] [r]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-IH "HR-IH (Descript)" "S 235 EN 10025-2" 200 100 6 10 15

Hot rolled L

Macro type:

HR-L

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| tw | Web thickness |

| tf | Flange thickness |

| r1 | Inner corner rounding radius |

| r2 | Inner edge rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [tw] [tf] [r1] [r2]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-L "HR-L (Descript)" "S 235 EN 10025-2" 100 100 10 10 12 6

Hot rolled U

Macro type:

HR-U

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| tw | Web thickness |

| tf | Flange thickness |

| r1 | Inner corner rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [tw] [tf] [r1]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-U "HR-U (Descript)" "S 235 EN 10025-2" 200 80 6 11 13

Hot rolled circular hollow section

Macro type:

HR-CHS

Parameters:

| Notation | Definition |

|---|---|

| d | Outer diameter |

| t | Plate thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [d] [t]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-CHS "HR-CHS (Descript)" "S 235 EN 10025-2" 300 18

Hot rolled T

Macro type:

HR-T

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| tf | Flange thickness |

| tw | Web thickness |

| r | Corner rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [tf] [tw] [r]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-T "HR-T (Descript)" "S 235 EN 10025-2" 200 100 10 6 12

Flat shape

Macro type:

HR-FS

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| t | Plate thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [t]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-FS "HR-FS (Descript)" "S 235 EN 10025-2" 300 25

Hot rolled rectangular hollow section

Macro type:

HR-RHS

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| t | Plate thickness |

| r | Corner rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [t] [r]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-RHS "HR-RHS (Descript)" "S 235 EN 10025-2" 100 80 8 20

Round bar

Macro type:

HR-RB

Parameters:

| Notation | Definition |

|---|---|

| d | Diameter |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [d]

Sample code

LOAD_SECTION_MACRO Sec_ID1 HR-RB "HR-RB (Descript)" "S 235 EN 10025-2" 20

Cold-formed sections

Cold-formed rectangular hollow section

Macro type:

CF-RHS

Parameters:

| Notation | Definition |

|---|---|

| h | Height |

| b | Flange width |

| t | Plate thickness |

| r | Corner rounding radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [t] [r]

Sample code

LOAD_SECTION_MACRO Sec_ID1 CF-RHS "CF-RHS (Descript)" "S 235 EN 10025-2" 100 80 5 15

Cold-formed circular hollow section

Macro type:

CF-CHS

Parameters:

| Notation | Definition |

|---|---|

| d | Outer diameter |

| t | Plate thickness |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [d] [t]

Sample code

LOAD_SECTION_MACRO Sec_ID1 CF-CHS "CF-CHS (Descript)" "S 235 EN 10025-2" 300 18

Cold-formed L

Macro type:

CF-L

Parameters:

| Notation | Definition |

|---|---|

| h | Section height |

| b | Section width |

| t | Plate thickness |

| r | Radius |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] [Macro type] [Section name] [Material name] [h] [b] [t] [r]

Sample code

LOAD_SECTION_MACRO Sec_ID1 CF-L "CF-L (Descript)" "S 235 EN 10025-2" 400 300 20 30

Cold-formed C

A simplified version for loading cold-formed C sections is available within the LOAD_SECTION_MACRO command. This simplified version has limited options for stiffener definition. The cold-formed C section can only be defined with single folded edge stiffeners witin the LOAD_SECTION_MACRO command. For more detailed stiffener options use the LOAD_SECTION_MACRO_STIFFENED command.

Macro type:

CF-C

Parameters:

| Notation | Definition |

|---|---|

| h | Section height [mm] |

| b1 | Upper flange width [mm] |

| b2 | Lower flange width [mm] |

| t | Thickness [mm] |

| R | Rounding radius [mm] |

| c1 | Top edge stiffener length [mm] |

| alpha1 | Top edge stiffener folding angle [°] |

| c2 | Bottom edge stiffener length [mm] |

| alpha2 | Bottom edge stiffener folding angle [°] |

| Forming method | Forming method (optional parameter) |

| Thickness tolerance | Thickness tolerance (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] CF-C [Section name] [Material name] [h] [b1] [b2] [t] [R] [c1] [alpha1] [c2] [alpha2] [Forming method] [Thickness tolerance]

Forming method:

Valid inputs:

- Cold rolled (default)

- Press broken

- Other cold formed

Thickness tolerance:

Valid inputs:

- Normal (default)

- Special

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID1 CF-C "CF C (Descript)" "S350GD+Z EN10346" 150 90 100 2 4 20 120 30 90

All parameters:

LOAD_SECTION_MACRO Sec_ID1 CF-C "CF C (Descript)" "S350GD+Z EN10346" 150 90 100 2 4 20 120 30 90 "Cold rolled" Normal

Cold-formed Z

A simplified version for loading cold-formed Z sections is available within the LOAD_SECTION_MACRO command. This simplified version has limited options for stiffener definition. The cold-formed Z section can only be defined with single folded edge stiffeners witin the LOAD_SECTION_MACRO command. For more detailed stiffener options use the LOAD_SECTION_MACRO_STIFFENED command.

Macro type:

CF-Z

Parameters:

| Notation | Definition |

|---|---|

| h | Section height [mm] |

| b1 | Upper flange width [mm] |

| b2 | Lower flange width [mm] |

| t | Thickness [mm] |

| R | Rounding radius [mm] |

| c1 | Top edge stiffener length [mm] |

| alpha1 | Top edge stiffener folding angle [°] |

| c2 | Bottom edge stiffener length [mm] |

| alpha2 | Bottom edge stiffener folding angle [°] |

| Forming method | Forming method (optional parameter) |

| Thickness tolerance | Thickness tolerance (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] CF-Z [Section name] [Material name] [h] [b1] [b2] [t] [R] [c1] [alpha1] [c2] [alpha2] [Forming method] [Thickness tolerance]

Forming method:

Valid inputs:

- Cold rolled (default)

- Press broken

- Other cold formed

Thickness tolerance:

Valid inputs:

- Normal (default)

- Special

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID1 CF-Z "CF Z (Descript)" "S350GD+Z EN10346" 150 90 100 2 4 20 120 30 90

All parameters:

LOAD_SECTION_MACRO Sec_ID1 CF-Z "CF Z (Descript)" "S350GD+Z EN10346" 150 90 100 2 4 20 120 30 90 "Cold rolled" Normal

Double mirrored sections

Double mirrored C

Double mirrored cold-formed C section.

Macro type:

DM-C

Parameters:

| Notation | Definition |

|---|---|

| Base section ID | Base section ID |

| a | Gap [mm] |

| Consider Eff DeltaMz | Consider Eff DeltaMz (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] DM-C [Section name] [Base section ID] [Gap] [Consider Eff DeltaMz]

Base section ID:

Two sections with this ID will form the double mirrored section. Only cold-formed C sections are accepted. The double mirrored section will inherit its material from this section. Section ID or section name is accepted with this syntax: "NAME: [SectionName]".

Consider Eff DeltaMz:

This setting controls if the shift of the effective centroid around the weak axis should be considered for the effective section model. This is an optional parameter.

Valid inputs:

- 1 (default)

- 0

If it is set to "1" then the shift will be considered.

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID2 DM-C "Double mirrored C (Descript)" Sec_ID1 10

All parameters + prerequisites (loading base section):

LOAD_SECTION_MACRO Sec_ID1 CF-C "CF C (Descript)" "S350GD+Z EN10346" 150 90 100 2 4 20 120 30 90

LOAD_SECTION_MACRO Sec_ID2 DM-C "Double mirrored C (Descript)" Sec_ID1 10 0

Double mirrored Sigma

Double mirrored cold-formed Sigma section.

Macro type:

DM-SIGMA

Parameters:

| Notation | Definition |

|---|---|

| Base section ID | Base section ID |

| a | Gap [mm] |

| Consider Eff DeltaMz | Consider Eff DeltaMz (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] DM-SIGMA [Section name] [Base section ID] [Gap] [Consider Eff DeltaMz]

Base section ID:

Two sections with this ID will form the double mirrored section. Only cold-formed Sigma sections are accepted. The double mirrored section will inherit its material from this section. Section ID or section name is accepted with this syntax: "NAME: [SectionName]".

Consider Eff DeltaMz:

This setting controls if the shift of the effective centroid around the weak axis should be considered for the effective section model. This is an optional parameter.

Valid inputs:

- 1 (default)

- 0

If it is set to "1" then the shift will be considered.

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID4 DM-SIGMA "Double mirrored sigma (Descript)" Sec_ID3 11

All parameters + prerequisites (loading base section):

LOAD_SECTION_MACRO_STIFFENED Sec_ID3 CF-SIGMA "CF SIGMA (Descript)" "S350GD+Z EN10346" 150 90 90 2 4 40 40 50 20

LOAD_SECTION_MACRO Sec_ID4 DM-SIGMA "Double mirrored sigma (Descript)" Sec_ID3 11 0

Double mirrored user drawn

Double mirrored cold-formed user drawn section.

Macro type:

DM-UD

Parameters:

| Notation | Definition |

|---|---|

| Base section ID | Base section ID |

| a | Gap [mm] |

| Consider Eff DeltaMz | Consider Eff DeltaMz (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] DM-UD [Section name] [Base section ID] [Gap] [Consider Eff DeltaMz]

Base section ID:

Two sections with this ID will form the double mirrored section. Only cold-formed user drawn sections are accepted. The double mirrored section will inherit its material from this section. Section ID or section name is accepted with this syntax: "NAME: [SectionName]".

Consider Eff DeltaMz:

This setting controls if the shift of the effective centroid around the weak axis should be considered for the effective section model. This is an optional parameter.

Valid inputs:

- 1 (default)

- 0

If it is set to "1" then the shift will be considered.

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID5 DM-UD "Double mirrored User drawn (Descript)" $Sec_ID 12

All parameters + prerequisites (retrieving base section ID):

A user drawn section can not be created from Descript code as of Consteel 18 build 4001, so this step has to be done manually. Although, if you create a cold-formed user drawn section, which is now the only section in the model, you can create the double mirrored section from it with the following code:

GET_LOADED_SECTIONS Loaded_Sections

ARRAY_GET Loaded_Sections 0 Base_Sec_ID

LOAD_SECTION_MACRO Sec_ID5 DM-UD "Double mirrored User drawn (Descript)" $Base_Sec_ID 12 0

The code lists all the sections present in the model, retrieves the ID of the first one, and uses that as a base section to create the double mirrored section.

Reinforced concrete sections

Rectangular beam section

Rectangular reinforced concrete beam section with design option.

Macro type:

RC-BeamRect

Parameters:

| Notation | Definition |

|---|---|

| bc | Width [mm] |

| hc | Height [mm] |

| ElasticMod | Modulus of elasticity (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] RC-BeamRect [Section name] [Material name] [bc] [hc] [ElasticMod]

Modulus of elasticity:

Modulus of elasticity applied in structural analysis.

Valid inputs:

- Ecm

- Ecd (default)

- EcdEff

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-BeamRect "RC-BeamRect (Descript)" "C25/30 EN 1992-1-1:2010" 333 555

All parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-BeamRect "RC-BeamRect (Descript)" "C25/30 EN 1992-1-1:2010" 333 555 Ecm

Rectangular column section

Rectangular reinforced concrete column section with design option.

Macro type:

RC-ColRect

Parameters:

| Notation | Definition |

|---|---|

| bc | Width [mm] |

| hc | Height [mm] |

| ElasticMod | Modulus of elasticity (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] RC-BeamRect [Section name] [Material name] [bc] [hc] [ElasticMod]

Modulus of elasticity:

Modulus of elasticity applied in structural analysis.

Valid inputs:

- Ecm

- Ecd (default)

- EcdEff

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-ColRect "RC-ColRect (Descript)" "C25/30 EN 1992-1-1:2010" 255 567

All parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-ColRect "RC-ColRect (Descript)" "C25/30 EN 1992-1-1:2010" 255 567 Ecm

Circular column section

Circular reinforced concrete column section with design option.

Macro type:

RC-ColCirc

Parameters:

| Notation | Definition |

|---|---|

| d | Diameter [mm] |

| ElasticMod | Modulus of elasticity (optional parameter) |

Parameter notations substituted into the command syntax:

LOAD_SECTION_MACRO [Object ID] RC-BeamRect [Section name] [Material name] [d] [ElasticMod]

Modulus of elasticity:

Modulus of elasticity applied in structural analysis.

Valid inputs:

- Ecm

- Ecd (default)

- EcdEff

Sample code

Minimal parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-ColCirc "RC-ColCirc (Descript)" "C25/30 EN 1992-1-1:2010" 444

All parameters:

LOAD_SECTION_MACRO Sec_ID1 RC-ColCirc "RC-ColCirc (Descript)" "C25/30 EN 1992-1-1:2010" 444 Ecm